Material Specification | Inconel ASME SB564, ASTM B564, ASME SB 865, ASME SB 637, ASME SB 462, ASME SB381, ASME SB 493, ASTM B 865, ASTM B 637, ASTM B 462, ASTM B381, ASTM B 493 |

Material Grades | Alloy 200, Nickel 200, N02200, Alloy 201, Nickel 201, N02201, Alloy 400, Monel 400, N04400, Alloy K-500, Monel K-500, N05500, Alloy 600, Inconel 600, N06600, Alloy 601, Inconel 601, N06601, Alloy 625, Inconel 625, N06625, Alloy 718, Inconel 718, N07718, Alloy 800, Incoloy 800, N08800, Alloy 800H, Incoloy 800H, N08810, Alloy 800HT, Incoloy 800HT, N08811, Alloy 825, Incoloy 825, N08825, Alloy C-276, Hastelloy C-276, N10276, Alloy C-4, Hastelloy C-4, N06455, Alloy C-22, Hastelloy C-22, N06022, Alloy B-2, Hastelloy B-2, N10665, Alloy 20, Carpenter 20Cb3, N08020 |

Dimension Standards | |

ASME / ANSI B16.5 | Weld Neck Flanges, Slip On Flanges, Blind Flanges, Socket Weld Flanges, Screwed Flanges, Orifice Flanges, Lap Join Flanges, Long Weld Neck Flanges, 150 #, 300 #, 600 #, 900 #, 2500 # |

ASME B16.47/B16.48 | Spectacle Blinds, Spades, Spacers, Weld Neck Flanges, Blind Flanges, Orifice Flanges |

DIN Standard Flanges | EN 1092-1, Type 1, Type 2, Type 11, Type 13, Type 5, PN6, PN10, PN16, PN25, PN40 |

UNI NORM Flanges | UNI 2276, 2277, 2278, 6089, 6090, 2280, 2281, 2282, 2283, 2284, 2253, 2254, 6092, 6093 |

DIN NORM Flanges | DIN 2573, 2576, 2642, 2631, 2632, 2633, 2634, 2635, 2565, 2566, 2527 |

Certification | EN 10204 3.1 / 3.2 |

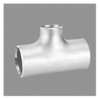

We are known as the leading organization offering an exclusive range of Monel 400 Lap Joint Flange.

Our offered joint flange is used to connect pipes or vessels to control

the flow of liquids. The offered joint flange is manufactured with the

help of ultimate quality basic material and cutting-edge techniques in

compliance with set industry standard. We are giving this joint flange

at competitive rates within a promised time frame.Features:

Seamac takes precise care about our packing as we make sure that our

goods reach our client in the same position in which it was dispatched

from our facility.Manufacturer: Seamac Piping Solutions Inc, Mumbai, India

- Fastening or closing the end of pipe

- Long life

- Perfect finish and corrosion resistance

- Serration as per customers’ requirements.

- Dimensionally 100% OK

- Ultrasonic Test 100% OK

- Dye Penetrant Test 100% OK

- IGC Test 100% OK

- Hardness 100% OK

- Chemical and Physically 100% OK

| Place of Origin | Not Given |

| Minimum Order Quantity | Not Given |

| Supply Ability | Not Given |

| Packaging Details | Not Given |

| Delivery Details | Not Given |

Not Given